Carbide burs are mainly used on pneumatic or electric grinder, the rotational speed is generally 6000-50000 rpm, and the use RPM of long shank burrs is around 50% of the conventional rotational speed.When use the burs,need to clamp the burrs tightly and fix the tools well.The cutting method is preferably up-cut milling to avoid reciprocating cutting.When working, the chips should be prevented from flying, and please use protective glasses.Please be attention:DON’T use too much force(the pressure generally does not exceed 4 kg) when operating.

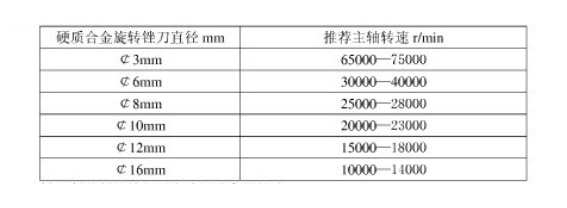

A reasonable operating speed is really important to achieve the desired degree of cut and workpiece quality.Increasing the speed can improve the machining quality and prolong the tool life, but may cause the burrs to break;Decreasing the speed helps to cut material quickly, but it may cause the system to overheat and fluctuate in cutting quality.Each type of carbide burs requires the appropriate operating speed to be selected for the specific operation.(Below is the recommended rotational speeds for reference)

If the workpiece is softer,please choose the higher rotational speed.

Contact: Julia Long

Phone: 86-15197383063

Tel: 86-731-22283096

Email: info@zyjcarbide.com

Add: No.52 Hongqi North Road,Shifeng District,Zhuzhou,Hunan,China